What is Asphalt, How is it Made, and How Much Does it Cost?

Publish on: 18-Mar-2025

Asphalt is one of the most popular construction materials. It is present on the roads we travel, the driveways where we park, and the roofs that shelter us. But have you ever wondered what asphalt actually is and how it is made? Let’s break it down simply.

What is Asphalt?

Asphalt is a mixture of bitumen (a thick, tar-like substance) and aggregates like sand, gravel, or crushed stone. This combination creates a strong, flexible surface that can handle heavy traffic and harsh weather.

When heated, asphalt is black and sticky, but it solidifies as it cools. Due to its durability and water-resistant properties, it is commonly used in road construction, roofing shingles, and waterproofing materials.

Why is Asphalt Popular?

- Durability – Lasts for years with proper maintenance.

- Flexibility – Expands and contracts with temperature changes without cracking easily.

- Cost-Effective – Cheaper than concrete and faster to install.

- Smooth Surface – Provides a comfortable driving experience with better traction.

What Color is Asphalt?

Asphalt is typically dark gray to black. Freshly laid asphalt appears jet black but fades to a lighter gray over time due to sunlight, weather, and traffic.

What is Asphalt Used For?

Asphalt is a versatile material widely used across industries. Some of its main applications include:

- Road Construction – Used for roads, highways, and parking lots due to its smooth and durable surface.

- Driveways and Pathways – Cost-effective and easy to maintain for residential and commercial properties.

- Roofing – Asphalt shingles are waterproof, durable, and provide insulation.

- Waterproofing – Used in buildings, bridges, and tunnels to prevent water damage.

- Sports Courts and Playgrounds – Common for basketball and tennis courts due to its durability.

- Dams and Reservoirs – Used to create waterproof linings and prevent seepage.

- Industrial Uses – Applied in flooring and manufacturing plants for its resistance to wear and tear.

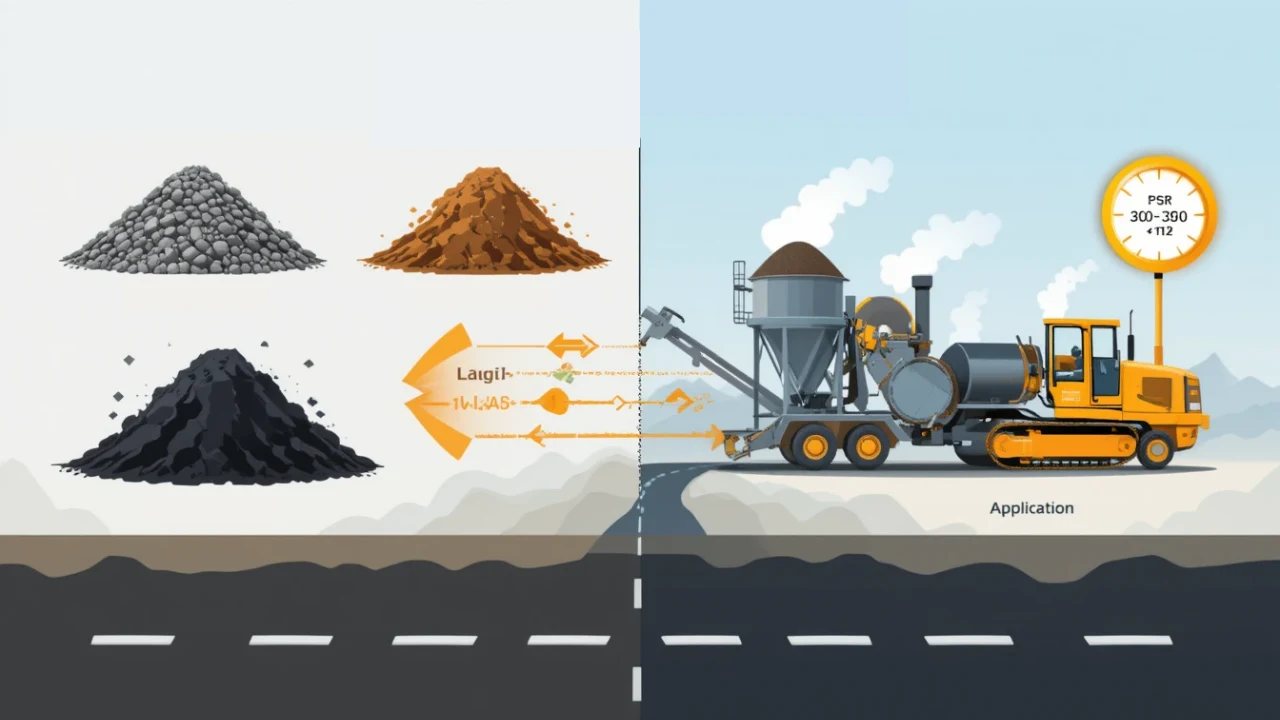

How is Asphalt Made?

Asphalt is produced by combining bitumen with aggregates through the following steps:

-

Sourcing Raw Materials

- Bitumen is refined from crude oil.

- Aggregates are collected from quarries or recycling facilities.

-

Heating and Mixing

- Bitumen is heated to 300–350°F (150–175°C) to become liquid.

- Aggregates are heated to remove moisture and improve bonding.

- The materials are mixed in a controlled ratio to form hot mix asphalt (HMA).

-

Cooling and Solidification

- As the asphalt cools, it hardens into a durable and flexible material.

- It undergoes quality testing to ensure strength and longevity.

Types of Asphalt Production

- Hot Mix Asphalt (HMA) – Heated and mixed at high temperatures for strong, long-lasting surfaces.

- Warm Mix Asphalt (WMA) – Produced at lower temperatures to reduce emissions and energy consumption.

- Cold Mix Asphalt – Used for temporary repairs, made without heating the materials.

How Much Does Asphalt Cost?

The cost of asphalt depends on various factors:

-

Type of Asphalt

- Hot Mix Asphalt (HMA): $100–$200 per ton.

- Warm Mix Asphalt (WMA): Slightly cheaper than HMA.

- Cold Mix Asphalt: More expensive per ton due to its convenience.

-

Size of the Project

- Small driveways: $1,500–$5,000.

- Parking lots: $10,000–$50,000+ depending on size.

- Road paving: $5–$10 per square foot.

-

Location and Material Availability

- Prices vary based on local demand, labor costs, and transportation fees.

-

Additional Costs

- Excavation and preparation: Removing old pavement or leveling the ground adds to costs.

- Sealcoating and maintenance: Protects the surface and extends its life, costing $0.20–$0.50 per square foot.

How much asphalt do i need?

To calculate how much asphalt you need, use the following formula or you can use this online asphalt calculator.

Formula to Calculate Asphalt Volume

Let:

- V = Volume of asphalt required (cubic feet or cubic yards)

- A = Area to be paved (square feet)

- T = Thickness of asphalt (in inches)

Formula for Volume in Cubic Feet:

(This converts inches into feet for consistent units.)

Formula for Volume in Cubic Yards:

(Since 1 cubic yard = 27 cubic feet, and 12 × 27 = 324.)

Step-by-Step Calculation:

Find the total area:

Determine the required thickness in inches. (Common values: 2 inches for driveways, 4-6 inches for roads.)

Calculate the volume in cubic feet using:

Convert to cubic yards (if needed):

FAQ

1. When was asphalt invented?

Asphalt has been used for thousands of years. The earliest known use dates back to about 625 B.C. in ancient Babylon, where it was used for road construction. The Romans also used asphalt to seal aqueducts and reservoirs.

Modern asphalt paving began in 1870 when Edmund J. DeSmedt, a Belgian chemist, laid the first asphalt road in the U.S. in Newark, New Jersey. Since then, asphalt technology has advanced, making it one of the most widely used materials in road construction today.

2. How to Remove Oil Stains from an Asphalt Driveway?

Oil stains on an asphalt driveway can be unsightly and may weaken the surface over time. Here’s how you can remove them effectively:

1. Absorb Fresh Oil Spills

- If the spill is fresh, sprinkle cat litter, baking soda, or sawdust on the stain.

- Let it sit for a few hours to absorb the oil, then sweep it away.

2. Use Dish Soap and Water

- Apply grease-cutting dish soap directly to the stain.

- Scrub with a stiff brush and rinse with warm water.

3. Try a Commercial Degreaser

- Use an asphalt-safe degreaser or oil stain remover (available at auto or hardware stores).

- Follow the product instructions and rinse thoroughly.

4. Apply Baking Soda or Vinegar

- Sprinkle baking soda on the stain, scrub with a brush, and rinse.

- Alternatively, pour white vinegar, let it sit for 15 minutes, scrub, and rinse.

5. Use a Pressure Washer

- A pressure washer with detergent can help remove tough stains.

- Be careful not to damage the asphalt with high pressure.

6. Repeat if Necessary

- Stubborn stains may require multiple treatments for full removal.

For deep-set stains, you may need asphalt sealant to restore the surface after cleaning. Regular maintenance helps keep your driveway looking fresh!

Final Thoughts

Asphalt is a reliable, cost-effective material used in roads, driveways, and roofing. Made by mixing heated bitumen with aggregates, it is designed to withstand heavy traffic and harsh weather.

Understanding the costs and manufacturing process helps in making informed decisions for your asphalt projects. Whether for a small driveway or a major roadway, asphalt remains a smart and durable choice.

Recent Posts

How Much Rebar Do I Need? – A Complete Guide

How Much Epoxy Do You Need for Your Floor?

How to Calculate Yards of Concrete: A Simple Guide for Your Next Project

Difference Between Cement and Concrete: What You Need to Know

How to Calculate Tile for a Shower: A Beginner’s Step-by-Step Guide

Roof Truss: Picking the Right Thickness for Your Project

Concrete Slab Construction: Materials, Process & Thickness Rules

How to Calculate Square Feet of a Wall: A Beginner’s Step-by-Step Guide

What is Crown Molding? Its Pros, Cons, and Uses

What is MDF? A Complete Guide to Medium-Density Fiberboard

What is Concrete? History, Types, Costs, and Tips for Working with It

Drywall: A Complete Guide to Installation, Repair, and Finishing

Floor Wax Guide: Best Practices for Wood, Tile, and Hardwood Surfaces

Tar and Gravel Roofs: A Durable Roofing Solution for Modern Homes

What Masonry Sand Is and Its Uses

Building and Installing Post and Rail Fences

Best Plywood Types for Roofing: Strength, Durability, and Protection

Slope: Why It Matters and How to Define It

Roof Panels: Types, Installation, Costs, and Maintenance

Electric Fences: Installation, Costs, Testing, and How They Work

How to Calculate Acreage of an Irregular Lot?

How Deep Should a Patio Base Be? Expert Tips and Material Choices

Deck Posts: Types, Materials, Pros & Cons, and Spacing

Types of Stone Wall: A Complete Guide

Mild Steel vs Carbon Steel | What is the differance?

How Deep Should a Fence Post Be?

5052 vs. 6061 Aluminum: Key Differences and Best Uses

Carpet Area vs Built-Up Area: What’s the Difference and How to Calculate?